Refining of industrial parts

from the prototype to the series part

Glass Beads

Dry Ice

Synthetic Substance

Corundum

Powders

Prime

Our promise of quality

For us, quality means meeting and, if possible, exceeding customer requirements. To achieve this, we work with the latest technologies and innovative processes.

We strive for open and honest communication with our customers and business partners and thus promote long-term customer relationships.

All quality-related processes are documented and are subject to a continuous improvement and further development process. In order to document this quality striving by Strahlwerk DELUXE, the management decided to have it certified according to DIN EN ISO 9001:2015.

You can find our certificate here

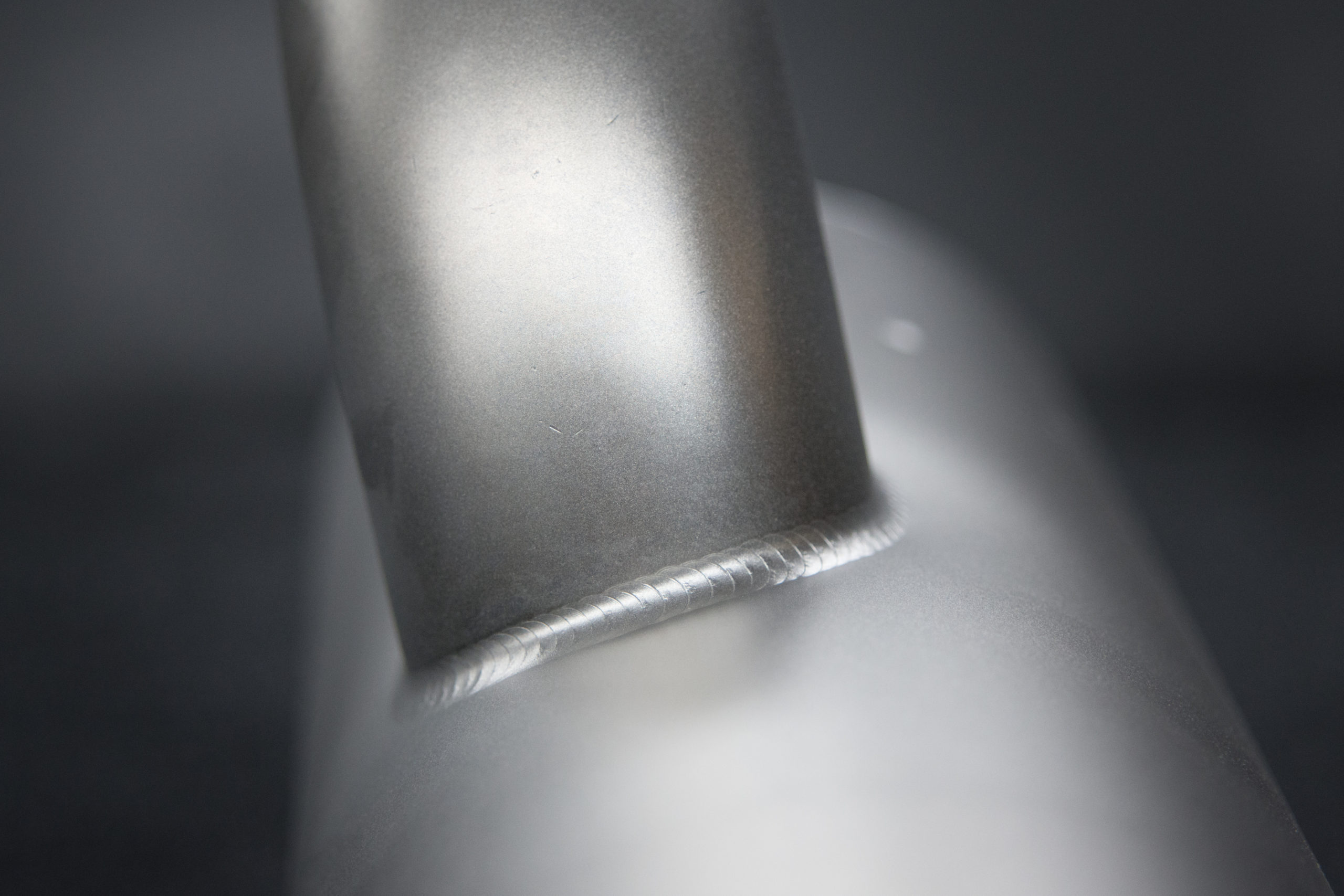

Glass Bead Blasting

Glass bead blasting was first used industrially in 1935. Today, this type of blasting is a proven and widely used surface finishing process, as it is extremely versatile. Protection against corrosion, removal of worn layers and optimization of aesthetics are the three main tasks of glass bead blasting.

We use this process to treat metallic surfaces. It is used when materials need to be cleaned particularly gently - for example to remove tarnish and traces of work that occur during welding.

Glass bead blasting is particularly suitable for cleaning, sweeping (roughening), matting, smoothing and deburring. The blasting technique is used to create matt or satin-gloss surfaces and to conceal surface defects in the material.

Sweeping is a particularly gentle blasting technique used to roughen surfaces. This improves the adhesion properties for later application of a coating/varnish. We use this process in connection with glass beads for aluminum parts, for example.

For stainless steel parts from medical technology, the food industry, optics, the pharmaceutical industry, etc., we have a special blasting room in which we only process stainless steel parts without ferrite, so that there is no contamination with other metals.

Cutting surfaces, sealing surfaces, flanges, threads, etc. are covered if necessary.

Dimensions glass bead blasting cabin for pure stainless steel processing:

L: 4,8 m, B: 4,5 m, H: 2,4 m

Dimensions of the combined glass beads/plastic blast cabinet:

L: 8,7 m, B: 4,1 m, H: 2,9 m

We would be happy to advise you personally on the various options and make you an individual offer. Please contact us.

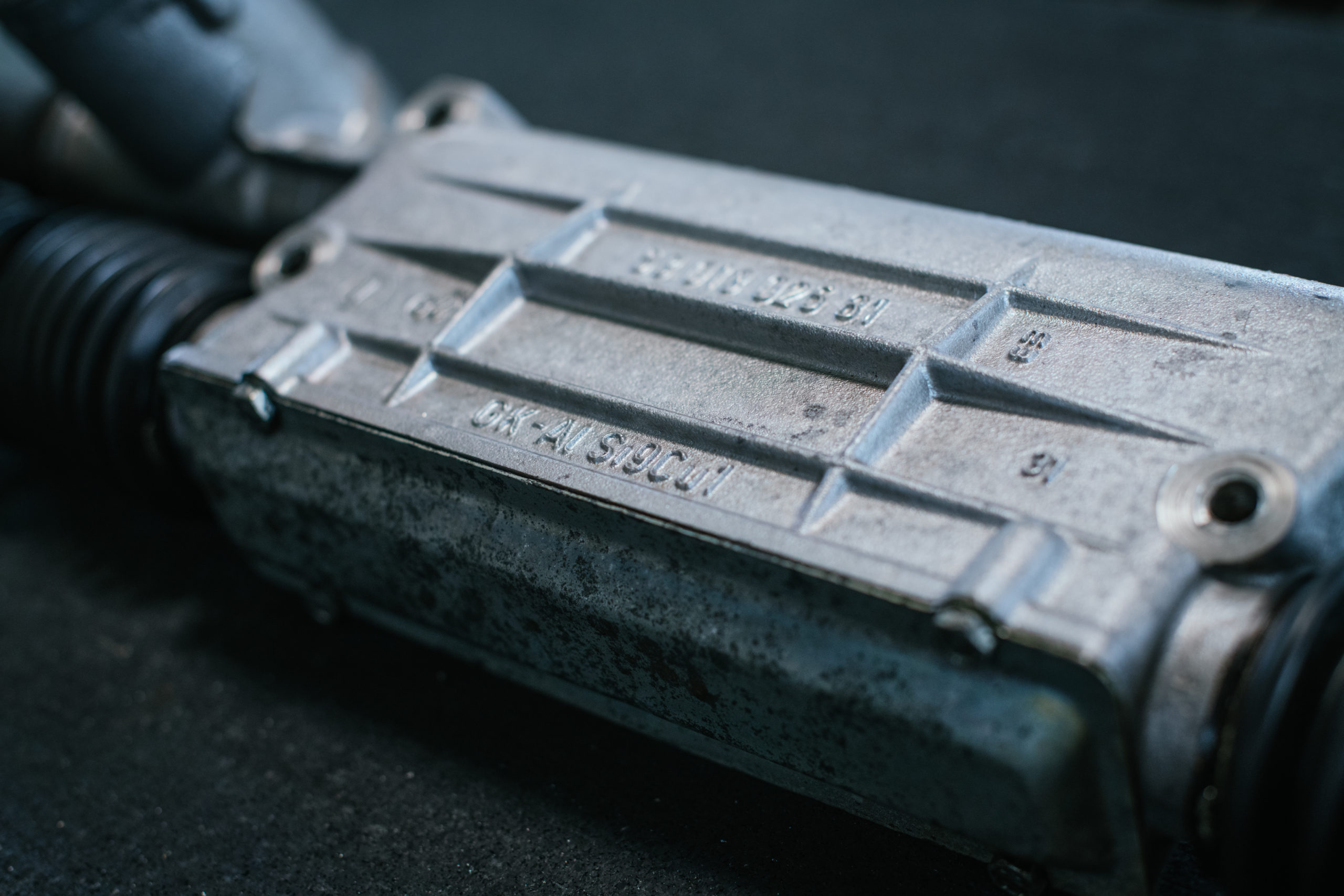

Dry Ice Blasting

With dry ice blasting, the finest dry ice granules (-79°) are blown at high speed onto the surfaces to be cleaned.

Dirt, adhesive residue and deposits become hard due to the cold (shock frozen) and flake off without damaging sensitive surfaces (e.g. bearing seats, sealing surfaces, threads, cables, rubber, etc.) or paint layers.

We use this method to clean e.g. machine parts/techn. Components that arise during maintenance or repair work. Normally, these parts have to be cleaned with great effort and using various chemicals. Save time and valuable resources and let us clean your parts professionally and gently.

The scope is almost infinite. After consultation, we can respond individually to your wishes and ideas.

Dimensions of the dry ice blasting cabin: L: 9.0 m, W: 4.6 m, H: 5.2 m

We would be happy to advise you personally on the various options and make you an individual offer. Please contact us.

Plastic Blasting

This is one of the gentlest processes and is particularly suitable for thin-walled, sensitive sheet metal and cast parts.

We use this gentle process to clean e.g. industrial molds without damaging or contaminating the surface.

When blasting plastic, no heat is generated and therefore there is no risk of warping as with other blasting media.

It is a non-abrasive blasting process, i. H. the surface is not roughened or attacked.

Plastic blasting is gentle on the material, dry and without the use of chemicals.

Dimensions of the plastic blasting cabin: L: 8.7 m, W: 4.1 m, H: 2.9 m

We would be happy to advise you personally on the various options and make you an individual offer. Please contact us!

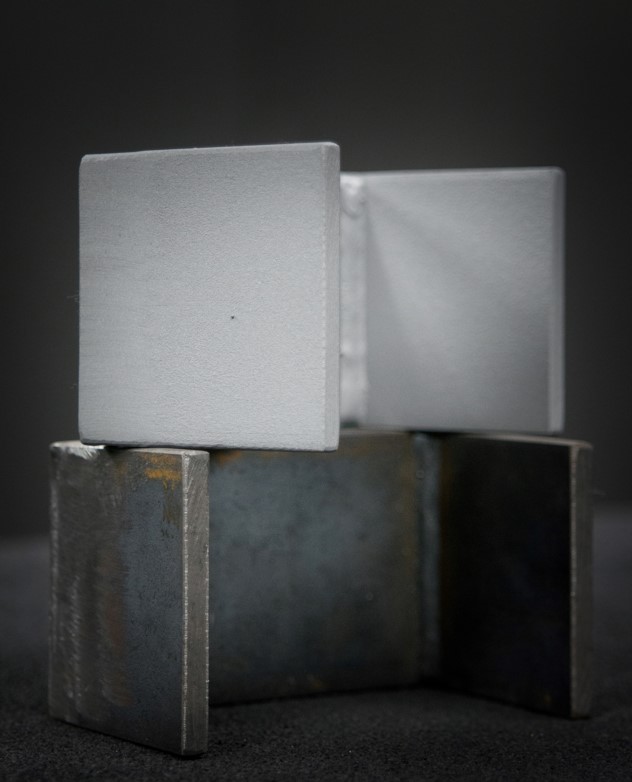

Corundum Blasting

Corundum is an iron-free, synthetic blasting agent which is extremely hard and tough and is characterized by increased abrasiveness, particularly due to its sharp edges.

The process is therefore particularly suitable for removing layers of rust, paint and scale from metal surfaces.

Sweeping is a particularly gentle blasting technique used to roughen surfaces. This improves the adhesion properties for later application of a coating/varnish. We use this process in connection with corundum, for example, for galvanized components, structural steel or aluminium.

Cutting surfaces, sealing surfaces, flanges, threads, etc. are covered if necessary.

Dimensions of the corundum blasting cabin: L: 10.0 m, W: 3.8 m, H: 2.9 m

We would be happy to advise you personally on the various options and make you an individual offer. Please contact us.

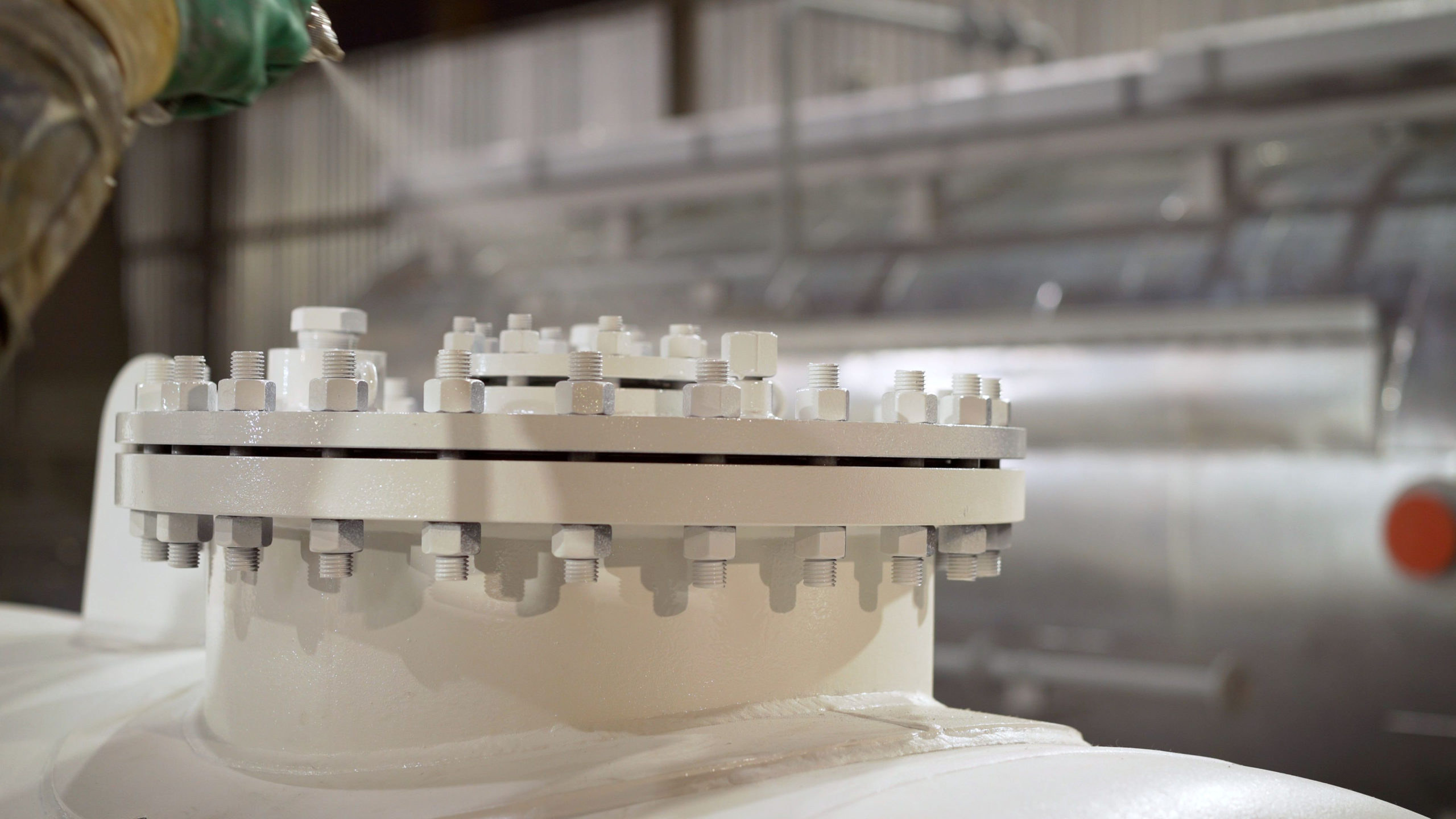

Powder Coating

In the case of classic powder coating or powder paintwork, the color powder is sprayed onto the workpiece using electrical field forces and then baked and fused.

A large number of surface effects such as smooth, finely or coarsely structured, matt or glossy are possible with the appropriate composition of the color powder.

Powder coated products are more resistant to moisture, chemicals, ultraviolet light and other extreme weather conditions. The risk of scratches, chips, abrasion, corrosion and other wear processes is significantly reduced.

We would be happy to advise you personally on the various options and make you an individual offer. Please contact us!

Prime

On request, the blasted parts/bodies can be provided with a 2K epoxy primer immediately after processing.

2k epoxy stands for two components that serve as an adhesion promoter, primer filler or primer. 2K Epoxy can be used as an anti-rust primer.

It can be painted over with conventional or water-dilutable 1K and 2K paints.

We would be happy to advise you personally on the various options and make you an individual offer. Give us a call!